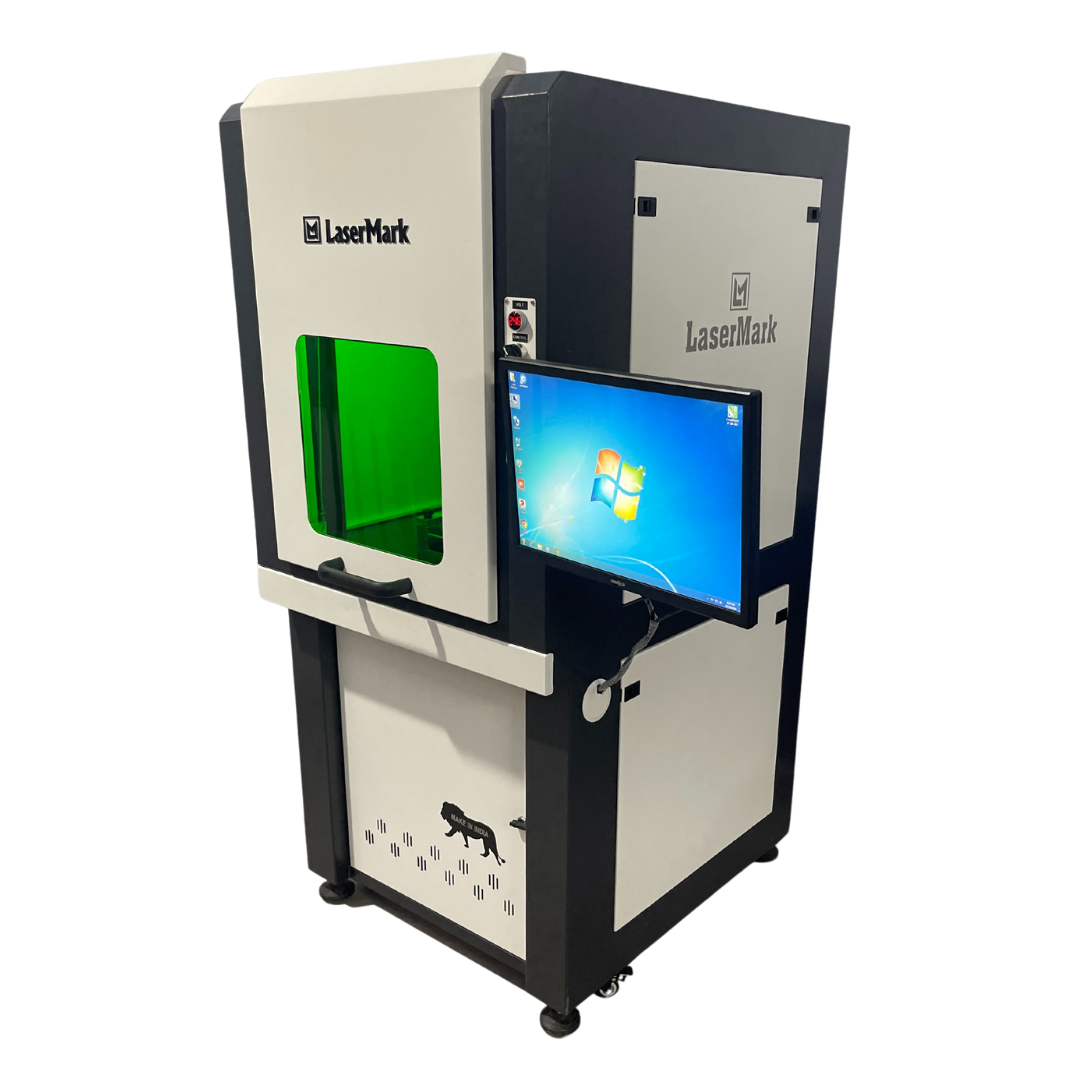

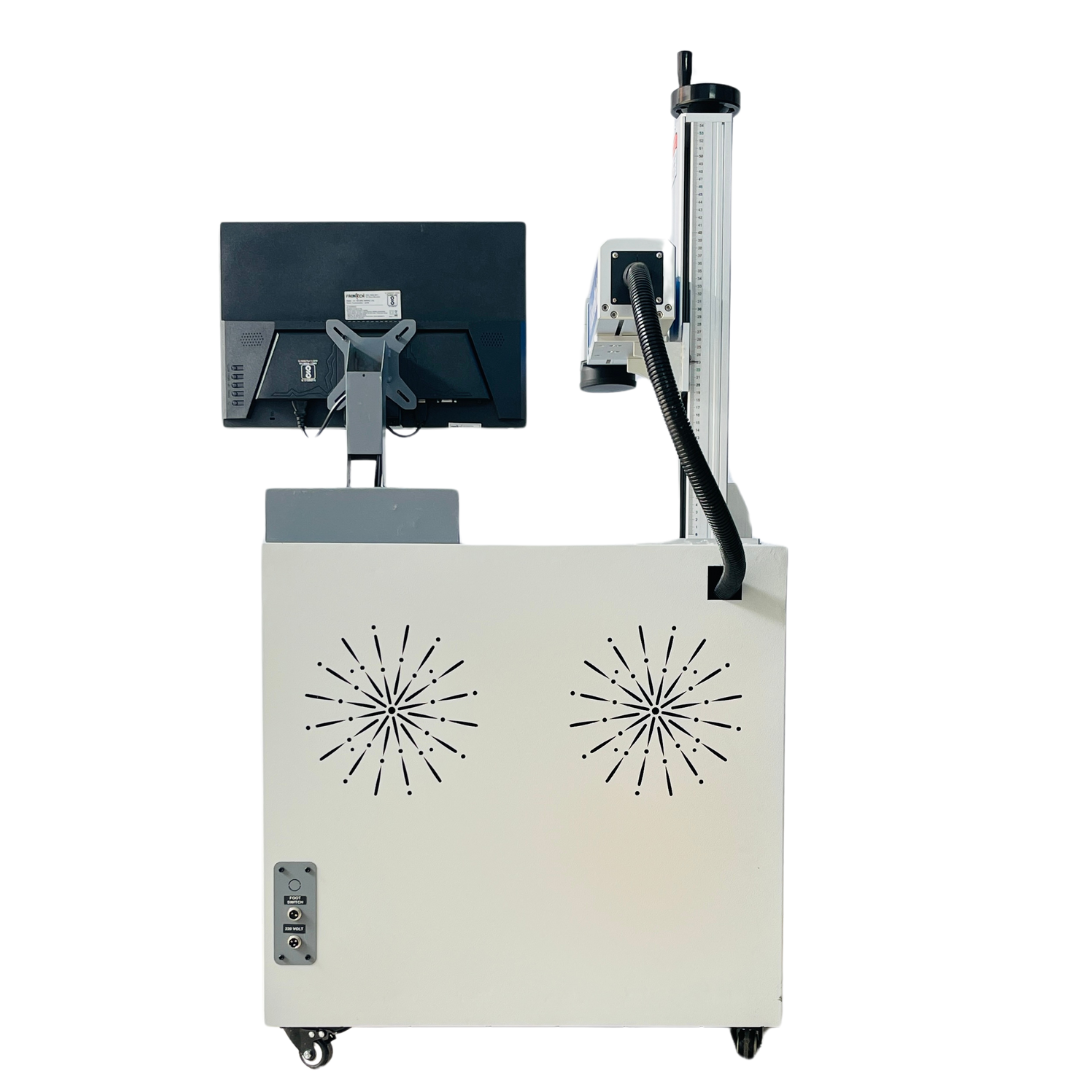

Jewellery Laser Cutting & Engraving Machine

GEM

Power: 60 & 100

Source Make: JPT

Reason To Buy

- Minimal Gold Waste

- High Accuracy

- Gold Recovery System

- Optimized Time Management

- Processing of Complex Shapes

- Ensured Quality Consistency

- User-Friendly Operation

Jewellery Laser Cutting & Engraving Machine

Product description:- Jewelry laser cutting and marking machines offer versatile solutions for cutting, shaping, and engraving various types of jewelry items, allowing jewelers to create unique and personalized designs with precision and accuracy. Whether it's cutting intricate patterns for gold wires or engraving name monograms on pendants, these machines enable the creation of high-quality and customized jewelry pieces for a wide range of applications.

| Parameters | Unit | GEM Specification |

|---|---|---|

| Laser Type | Fiber Laser | |

| Cutting Material | Gold, Silver & Brass | |

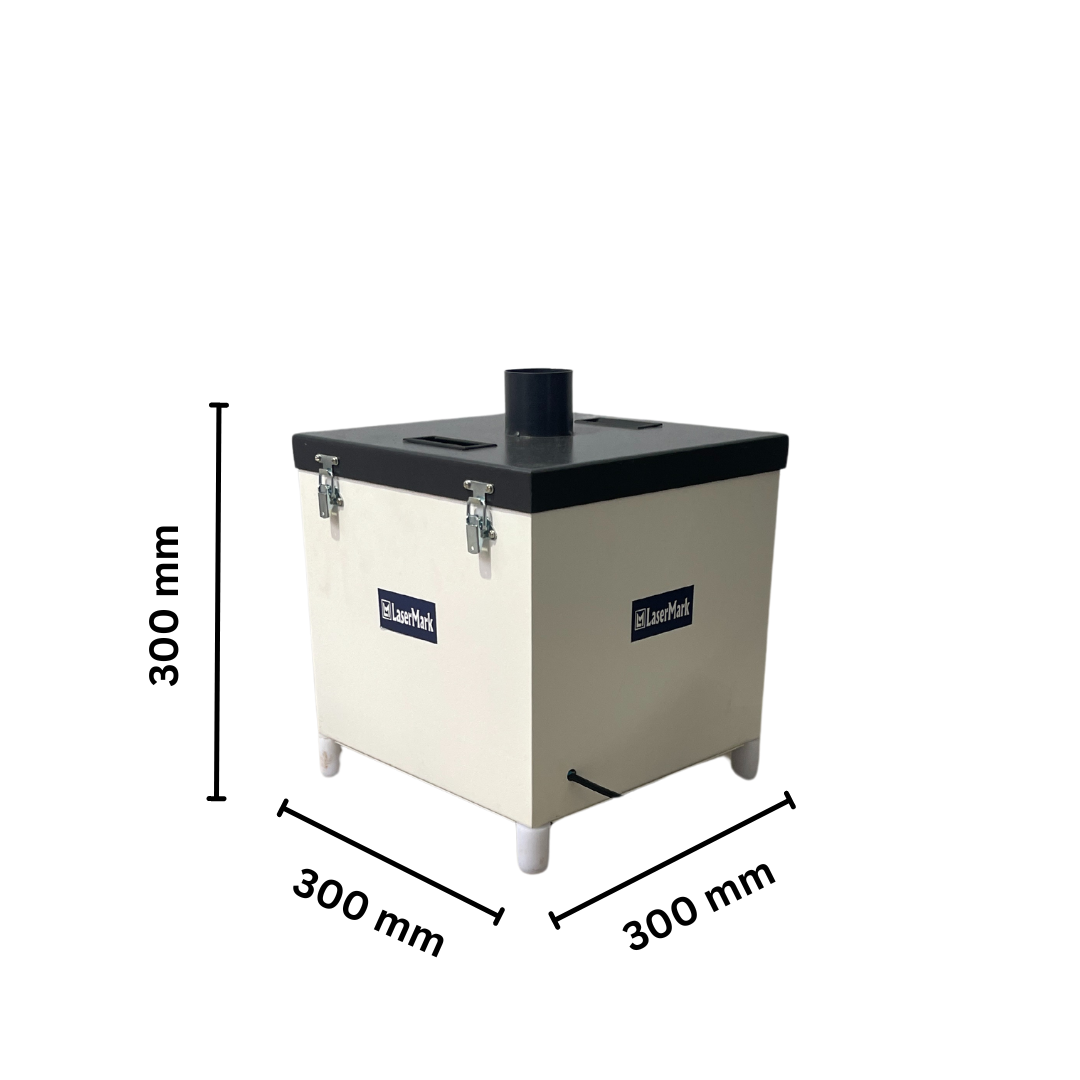

| Vacuum Unit | 1 - Number | Gold recovery System |

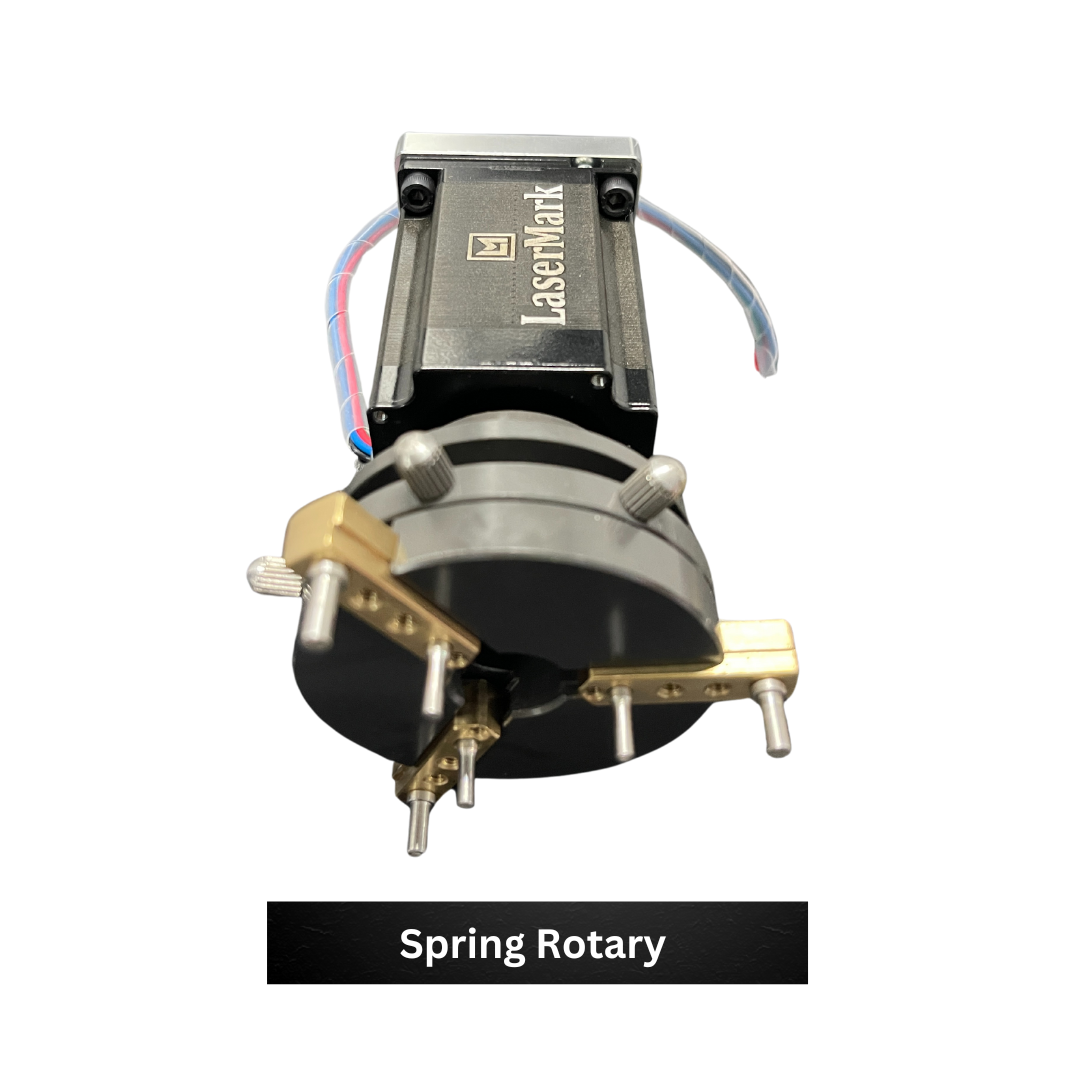

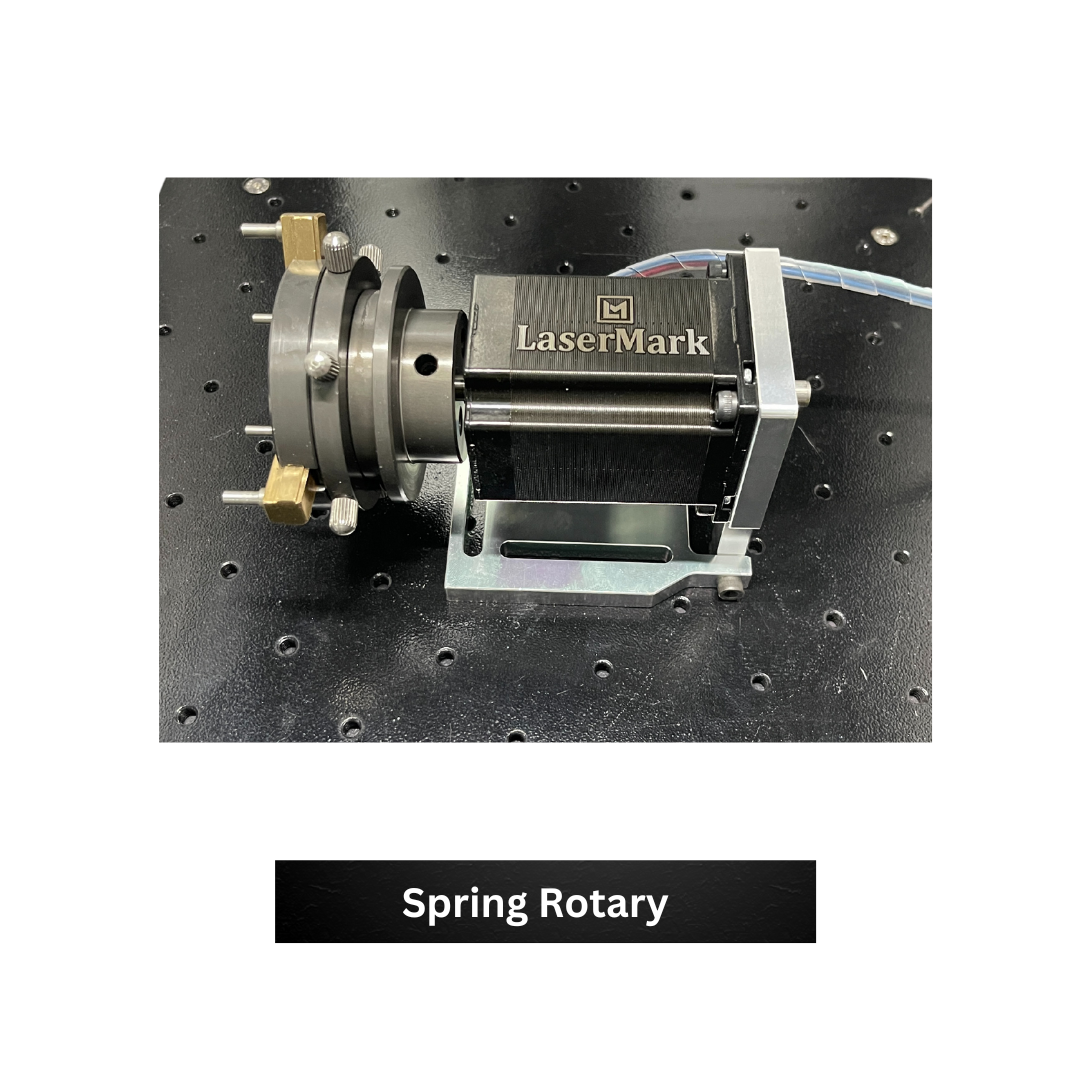

| Spring Rotary | 3” | |

| Laser Power | Watt | 60 & 100 |

| Laser Source Make | JPT | |

| Lens | F – Theta | |

| Working Area | mm | Maximum 180 X 180 |

| Z Axis (Manual ) | mm | Max,-550 Stepper Motorize |

| Software | EZCAD | |

| Laser Class | Class IV | |

| Mode of Operation | Q Pulsed | |

| Laser Wavelength | Nm | 1064 ±10 |

| Repeatability | Micron | ≤80 |

| Operating Temperature | Up to 40 °C | |

| Overall Size | mm | (L x W x H) = 850 x 750 x 1550 |

| Machine Weight | Kg | 150 |

| Cooling System | Air Cool | |

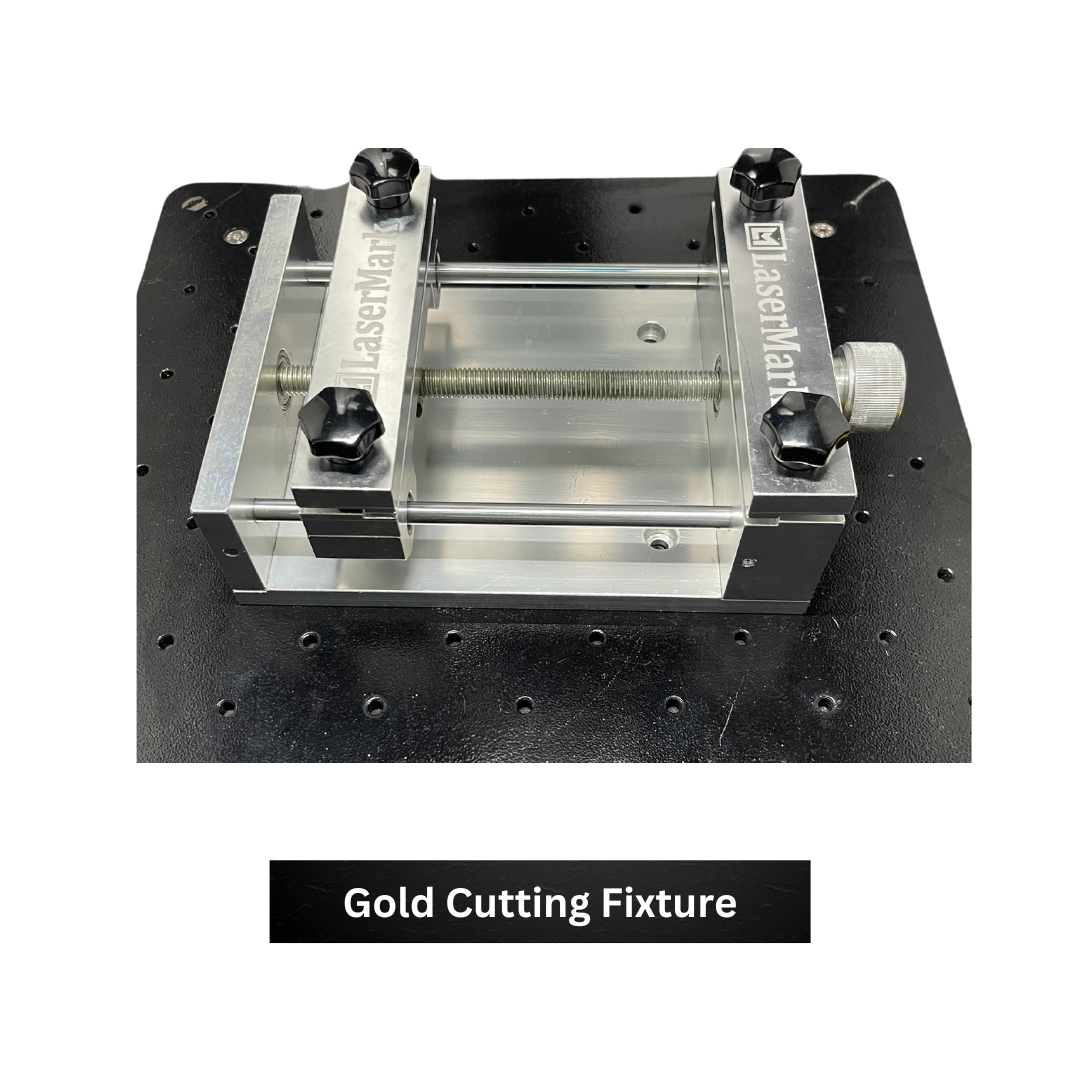

| Cutting Fixture | Screw Type | |

| Supporting Format | Support PLT, DXF, BMP File etc., Using SHX TTF Character Storage Directly |

* Technical specifications are subject to change without prior notice

- Gold/silver collection system to reduce waste: Has a special system to gather gold dust made during cutting, so less material is wasted, and the workspace stays clean.

- Cost-effective cutting: Can cut thick and thin metals efficiently and affordably, making sure the results are precise and high-quality.

- Highly flexible: Offers lots of choices in size, power, and features to match different jewelry designs and production needs.

- High accuracy cutting: Can handle complex shapes with great accuracy, making it easy to cut detailed and delicate jewelry pieces.

- Minimize Waste, Maximize Savings: Uses smart technology to save leftover precious metals and reduce waste, making it eco-friendly and cost-effective.

- Gentle Processing to Protect Your Work: Treats jewelry pieces gently during cutting, so they keep their shape and look perfect without any damage.

- Smooth Finish for Beautiful Results: Gives clean cuts and smooth edges to materials, ensuring the jewelry looks flawless and professional.

- Less Time Spent on Finishing Touches: Needs little or no extra work after cutting, which saves time and effort while still giving fantastic results.

- Easy Software for Quick Work: Comes with user-friendly software that's simple to use and has ready-made designs, speeding up production and making it easier.

- Strong and Reliable for Long-Term Use: Made with tough materials and top-quality parts, so it stays reliable and works perfectly for a long time.

- Small and Portable for Convenience: Designed to be compact and easy to move, saving space in the workshop and making it simple to use anywhere.

- Efficient Cutting with Less Downtime: Keeps cutting with little wasted time between jobs, like setting up or fixing problems, so it's always working at its best.

Jewelry laser cutting and marking machines are widely used in the jewelry industry for various applications due to their precision, efficiency, and versatility.

Here are some key applications: Gold Pendants, Earrings, Gold wires, Rings, Brooch, Name Monograms, Belt Buckles, Trinkets, Tiaras, Anklet, Crowns, Armlet, Bracelets etc.

- Gold & Silver Cutting: Gem laser machine can cut upto 1.6MM (14 Gauge) Gold and Silver cake.

- Custom Engraving: Engrave personalized messages, names, initials, dates, and unique designs on rings, bracelets, pendants, and other jewelry items.

- Hallmarking: Engrave quality marks, such as karat stamps and purity marks, to certify the metal content of jewelry pieces.

- Branding and Logos: Mark brand logos or trademarks on jewelry pieces for brand recognition and authenticity.

- Surface Texturing: Create textures and patterns on the surface of jewelry to enhance visual appeal and uniqueness.

- Security Features: Incorporate hidden or complex marks to prevent counterfeiting and ensure the authenticity of high-value items.

Engrave QR codes or barcodes for enhanced traceability and inventory management. - Material Efficiency: Minimize material wastage through precise cutting and marking, which is particularly important when working with expensive metals.