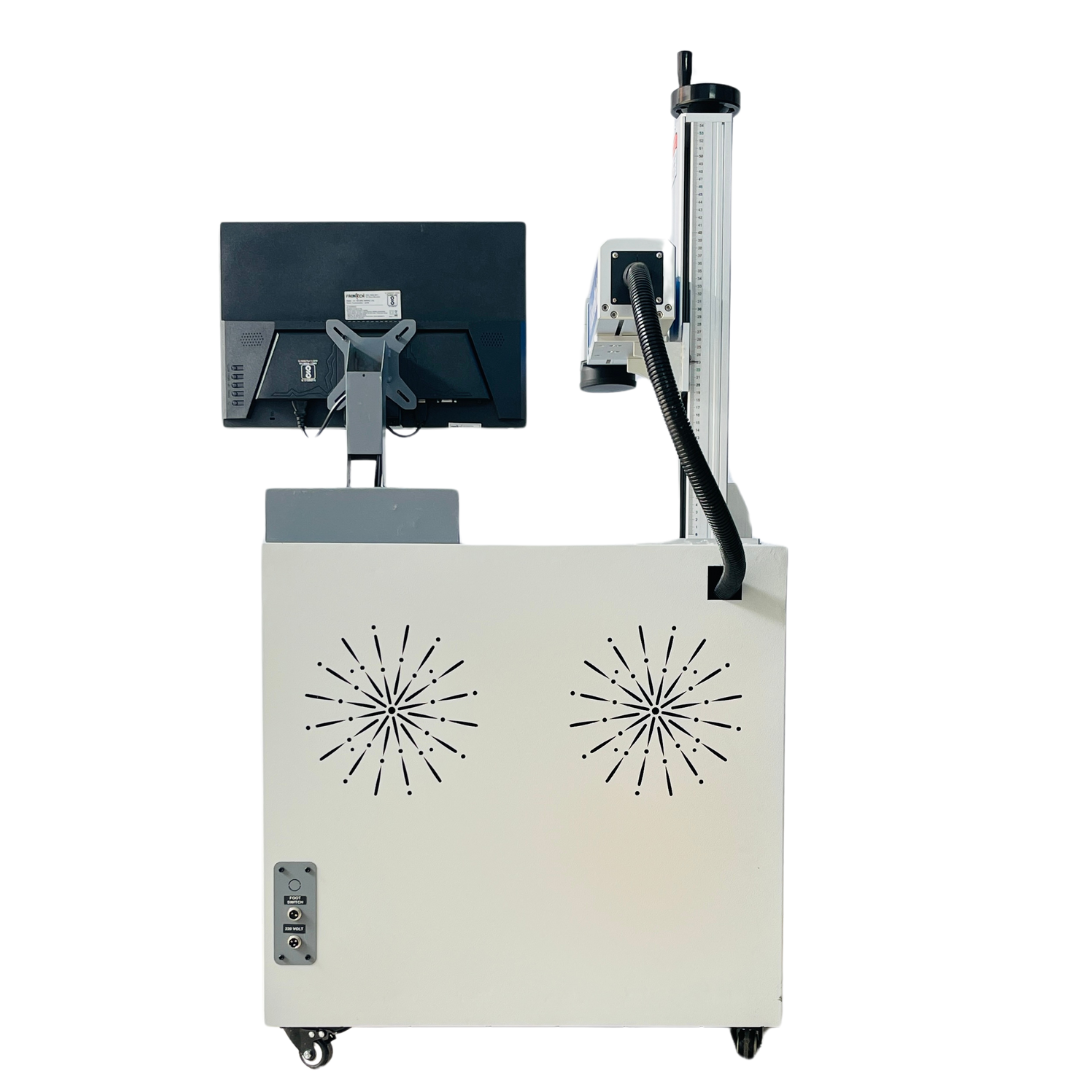

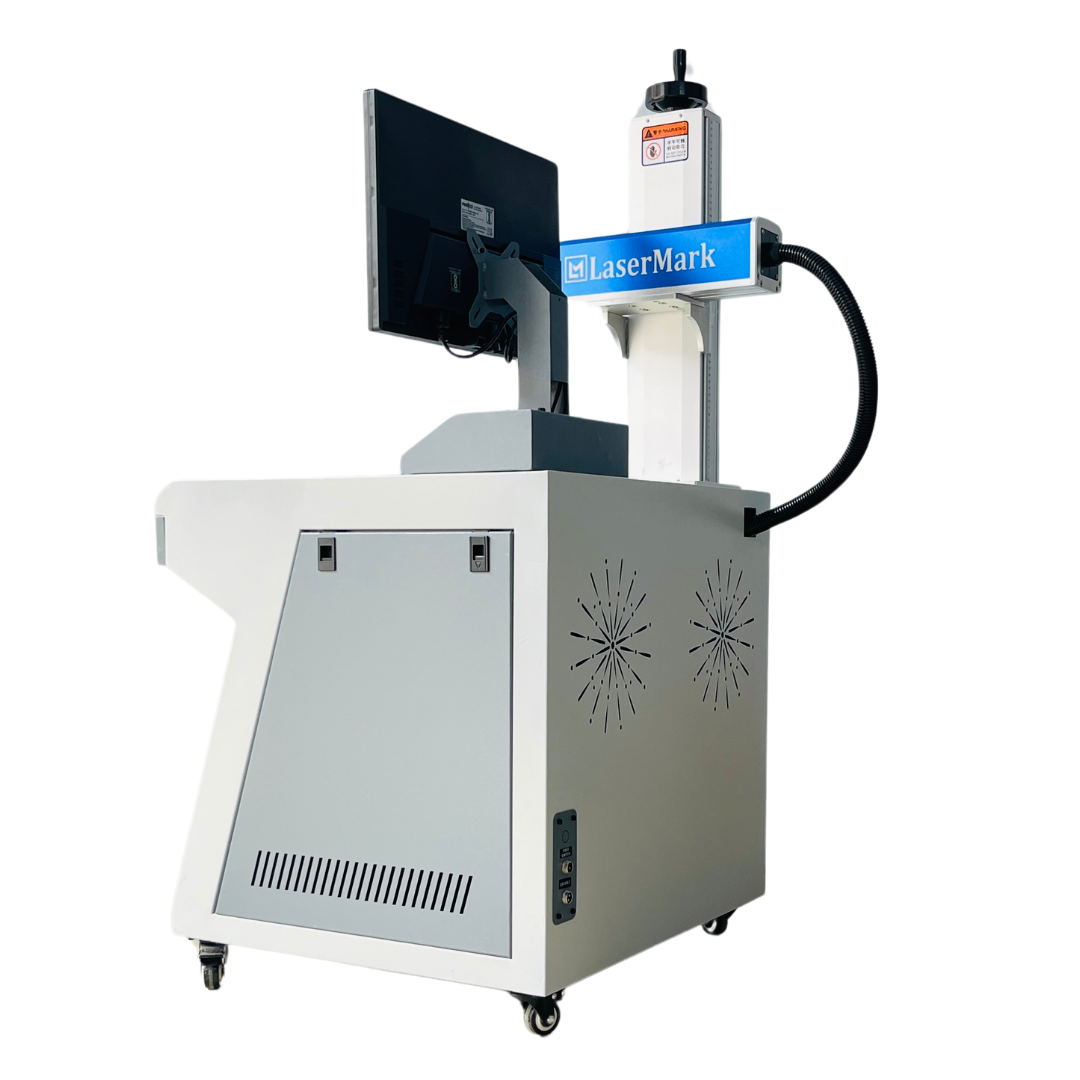

UV Laser Marking Machine

PRIME

Power: 3 | 5 | 10

Source Make: JPT

Marking | Engraving | Coding | Traceability | Printing

High Speed Marking & Engraving

UV Laser Marking Machine

Product description:- Introducing our cutting-edge UV laser marking machine, engineered for precision and versatility. With a compact design and advanced UV laser technology operating at 355nm, it delivers high-speed marking on various materials including plastics, glass, ceramics, and metals. Experience exceptional marking quality, user-friendly interface, and seamless integration into your production line. Elevate your marking capabilities with our UV laser marking solution.

| Parameters | Unit | PRIME Fiber - Specification |

|---|---|---|

| Laser Type | YAG Laser | |

| Laser Power | Watt | 3 | 5 | 10 |

| Laser Source Make | Watt | JPT |

| Lens | F – Theta | |

| Working Area | Mm | Maximum 300 X 300 |

| Z Axis (Manual / Motorized) | Mm | Min.-550, Max,-1200 |

| Software | EZCAD | |

| Laser Class | Class IV | |

| Mode of Operation | Pulsed Laser | |

| Laser Wavelength | Nm | 355 ±10 |

| Operating Temperature | Up to 35 °C | |

| Overall Size | Mm | (L x W x H) = 710 x 660 x 1345 |

| Machine Weight | Kg | 120 |

| Maximum Job Load | Kg | Max. -100 |

| Cooling System | 5 ltr tank | Water Cool |

| Supporting Format | Support PLT, DXF, BMP File etc., Using SHX TTF Character Storage Directly |

* Technical specifications are subject to change without prior notice

- UV Laser Source: Equipped with a high-quality UV laser source, typically operating at wavelengths around 355nm, providing the necessary energy for precise marking on various materials.

- High Precision Marking: Capable of achieving fine details and high-resolution marking due to the short wavelength of UV lasers, ensuring accuracy and quality in the marked output.

- Adjustable Marking Parameters: Allows users to adjust parameters such as laser power, marking speed, frequency, and pulse duration to optimize marking quality based on material type, desired mark depth, and application requirements.

- Dynamic Focusing System: UV laser marking machines feature dynamic focusing capabilities, enabling the focal point to adjust automatically or manually to maintain optimal marking quality on curved or uneven surfaces.

- Integrated Cooling System: Includes an efficient cooling system to maintain stable laser performance and prevent overheating during prolonged operation, ensuring consistent marking quality and longevity of the laser source.

- User-friendly Interface: Equipped with intuitive software interfaces and control panels for easy setup, operation, and monitoring of marking processes. Some machines may also support compatibility with CAD/CAM software for seamless design import and customization.

- Automated Marking Solutions: Advanced UV laser marking systems may incorporate automation features such as conveyor integration, rotary axis attachments, or robotic arms for batch processing and increased productivity.

- Real-time Monitoring and Quality Assurance: Offers real-time monitoring of marking processes with features like vision systems or camera integration to ensure mark accuracy, consistency, and traceability throughout production.

- Safety Features: Includes safety interlocks, beam shutters, and protective enclosures to prevent exposure to laser radiation and ensure operator safety in compliance with industry standards and regulations.

- Compact and Modular Design: Designed with a compact footprint and modular components for easy integration into existing production lines or workspaces, offering flexibility and scalability in manufacturing environments.

- Electronics Industry: UV laser marking machines are vital in the electronics industry, marking alphanumeric codes, serial numbers, QR codes, and barcodes on semiconductor chips, PCBs, connectors, and sensors. With non-contact precision, they ensure clear, legible marks on sensitive materials like silicon, ceramics, and plastics, enabling traceability, quality control, and anti-counterfeiting measures while maintaining high-speed production rates.

- Medical Device Manufacturing: UV laser marking machines are indispensable for engraving regulatory information, lot numbers, expiration dates, and UDIs on plastics, stainless steel, and titanium in medical device manufacturing. Offering precise marking without material compromise, they ensure compliance with stringent regulations, facilitating traceability throughout the product lifecycle and enabling anti-counterfeiting measures for patient safety and brand reputation.

- Automotive Industry: UV laser marking machines play a crucial role in marking VIN numbers, part numbers, logos, and batch codes on engine components, chassis, electronic modules, and automotive glass. With exceptional precision and durability, they create permanent, high-contrast marks on metal, plastic, and glass surfaces, ensuring essential traceability, quality assurance, and brand identification in automotive manufacturing processes.

- Aerospace and Defense Sector: Aerospace and defense manufacturers rely on UV laser marking machines to engrave part numbers, serial numbers, UID codes, and compliance markings on aluminum, titanium, and composites. Meeting military specifications, they ensure clear, permanent marks that enhance part identification, traceability, and maintenance tracking in highly regulated environments.

- Jewelry and Watch making: UV laser marking machines are indispensable for engraving logos, serial numbers, purity marks, and custom designs on precious metals like gold, silver, platinum, and stainless steel in the jewelry and watch making industry. Offering fine-detail engraving with minimal heat impact, they preserve the integrity and aesthetic appeal of delicate pieces, enhancing brand recognition, authenticity, and value perception.

- Packaging and Labeling: UV laser marking machines are essential for marking expiry dates, batch numbers, barcodes, and logos on packaging materials such as plastics, cardboard, and flexible films. Providing high-speed, high-resolution marking, they ensure product traceability, regulatory compliance, and brand consistency across diverse packaging formats. Their clean, non-contact marking solution eliminates the need for inks or labels, reducing packaging waste and enhancing sustainability.